The Ultimate Checklist for strapping machine repair and Routine Maintenance

Wiki Article

A Comprehensive Review of Strapping Machine Repair Techniques and Solutions

Strapping machines play a vital role in packaging operations, yet they commonly experience a variety of common concerns. From mechanical wear to improper placement, these issues can lead to inadequacies and downtime. Understanding the signs of breakdown and utilizing effective repair techniques is important. This overview outlines vital methods and devices necessary for maintenance and troubleshooting. strapping machine repair. Identifying when to deal with repairs independently or look for expert support can greatly affect overall performance.Typical Issues Dealt With by Strapping Machines

Strapping machines, crucial devices in product packaging operations, commonly experience an array of typical problems that can interfere with process. One constant issue is improper tensioning, which can bring about over-tightened or loose bands, eventually impacting package stability. Additionally, broken or used seals may cause weak links, jeopardizing the total protection of the product packaging. One more usual problem entails imbalance of the strapping course, creating jams or interruptions in the strapping cycle. Dirt and debris accumulation can further aggravate these troubles, bring about decreased maker effectiveness. Operators might additionally encounter electric malfunctions, such as faulty sensors, which can impede the equipment's automated functions. Inconsistent strapping speeds can lead to delays and ineffectiveness in manufacturing. Dealing with these problems promptly is vital for keeping peak performance and making certain a smooth product packaging process. Regular upkeep and troubleshooting are vital to decrease downtime and expand the durability of strapping machines.Determining Signs And Symptoms of Malfunction

Identifying signs and symptoms of malfunction in strapping machines is crucial for efficient repairs. Common mechanical issues commonly materialize as uncommon sounds or inconsistent strapping stress, while electric system failures might present as irregular operation or complete closures. Identifying these symptoms early can significantly minimize downtime and repair work costs.

Usual Mechanical Issues

Mechanical reliability is crucial for the efficient operation of strapping machines, yet different concerns can occur, causing breakdowns. Common mechanical issues include worn-out rollers, which may generate uneven stress or trigger the band to slip. Imbalance of parts can lead to jams, impeding the production process. Furthermore, concerns with the tensioning system, such as a defective springtime, can lead to irregular band tightness. Frayed belts or chains might likewise hinder activity, while harmed frames can compromise security. Operators should be alert for uneven operations or uncommon noises, as these might signal underlying mechanical failures. Trigger identification and resolution of these concerns are necessary to preserving ideal maker efficiency and stopping extended downtime.Electric System Failings

Malfunctions in the electrical system of strapping machines can significantly influence their efficiency, equally as mechanical issues do. Determining symptoms of electrical failing is vital for timely repair. Usual indicators include intermittent power loss, which might show up as the device closing down unexpectedly or falling short to begin. Additionally, abnormal noises, such as humming or clicking, can signal issues within the electrical components. A malfunctioning control panel may also present mistake codes or flickering lights, indicating underlying troubles. Overheating elements or charred fuses usually point to electrical overloads. Consistently monitoring these signs enables for very early discovery and treatment, eventually lessening downtime and enhancing the equipment's operational effectiveness. Understanding these indicators aids specialists in identifying and addressing electrical failings efficiently.Step-by-Step Repair Techniques

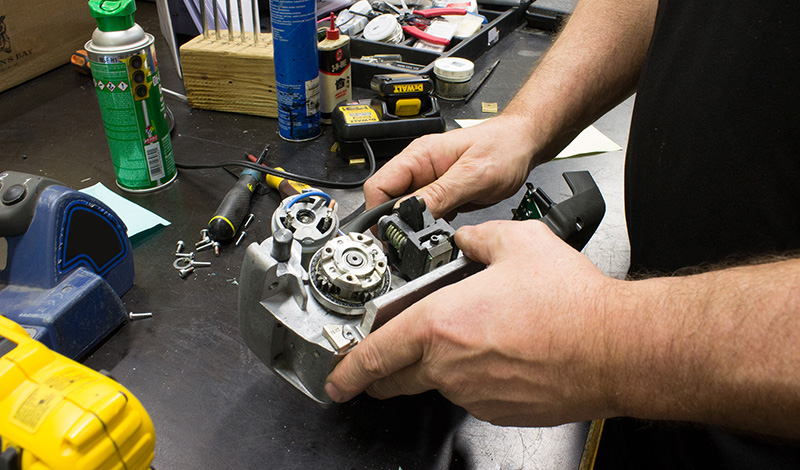

When addressing the fixing of a strapping maker, a methodical strategy is crucial to ensure resilient and effective remedies (strapping machine repair). The specialist ought to perform a detailed assessment to determine the origin cause of the malfunction. This entails checking for visible problems and making sure that all components are operating correctly. As soon as the issue is separated, the next action requires dismantling the device very carefully, documenting each action to help with reassemblyAfter disassembly, cleansing the interior parts is crucial, as dirt and particles can exacerbate problems. The professional needs to then replace any type of worn or broken parts, making certain compatibility with the existing system. Following repair services, reassembly should be carried out thoroughly, paying close focus to alignment and attachment. Examining the equipment under functional problems is important to confirm that repairs have resolved the concern, followed by routine upkeep checks to protect against future failures.

Tools and Devices for Effective Repairs

Efficient repairs of strapping machines count heavily on the right tools and tools. Specialists call for a selection of hand devices, consisting of wrenches, pliers, and screwdrivers, to address mechanical concerns successfully. In addition, specialized tools such as tensioning devices and sealers are crucial for guaranteeing appropriate strapping capability.Diagnostic devices, including oscilloscopes and multimeters, aids in identifying electrical mistakes, while air stress evaluates work for pneumatic systems. Having access to replacement components, such as belts and motors, enhances the repair work procedure, decreasing downtime.

Moreover, a well-appointed workstation with sufficient lighting and company enhances efficiency throughout repair services. Security gear, consisting of handwear covers and goggles, ensures the professional's protection from prospective hazards. By making use of the ideal tools and devices, service technicians can do repair services precisely, lengthening the life-span of strapping machines and maintaining functional productivity.

Preventative Maintenance Strategies

To assure the longevity and efficient procedure of strapping machines, implementing preventative maintenance strategies is crucial. Normal assessments play a vital function, allowing drivers to recognize wear and tear before it escalates right into considerable issues. Secret elements such as electric motors, belts, and rollers need to be taken a look at frequently for indicators of damages or imbalance.Lubrication of relocating components is another get redirected here essential facet, decreasing friction and protecting against premature wear. Operators must follow the manufacturer's guidelines for lubrication intervals and sorts of lubricants.

In addition, maintaining precise records of upkeep activities aids track the equipment's problem over time, ensuring that no significant facet is overlooked. By prioritizing these preventative steps, companies can enhance the dependability of their strapping machines, eventually reducing downtime and repair work prices.

Repairing Tips for Quick Fixes

Although strapping machines are designed for longevity, they can come across occasional problems that interfere with procedures. Determining and dealing with these issues quickly can minimize downtime. One usual concern is imbalance, which can typically be settled by examining the positioning of the strapping material and readjusting the overviews appropriately. If the maker stops working to band properly, operators must examine the tension setups and ensure that the movie is loaded correctly.One more regular concern is the presence of debris in the feed area. On a regular basis getting rid of any kind of obstructions can boost functionality. Furthermore, if electric parts seem unresponsive, confirming power links and weblink resetting circuit breakers can bring back procedure. Operators needs to likewise examine the sealing devices for deterioration, as worn components can result in inadequate seals. By applying these fixing pointers, drivers can successfully manage small problems and preserve the efficiency of strapping procedures.

When to Look For Expert Assistance

Acknowledging the indications of equipment breakdown is vital for maintaining functional efficiency. strapping machine repair. Looking for specialist help becomes required when repair services end up being intricate or safety worries emerge. Prompt treatment by specialists can stop further damage and ensure a safe workplace

Indications of Machine Breakdown

Exactly how can drivers determine when a strapping maker remains in distress? A number of indications indicate prospective breakdown. Unusual sounds, such as grinding or squealing, typically suggest mechanical problems. Irregular strapping high quality, characterized by loose or poorly secured straps, may indicate problems with tensioning or securing devices. In addition, frequent mistake messages on the control board can be a clear indicator that the device is not working properly. Operators must additionally check for too much resonances or overheating, which could direct to underlying mechanical failings. In addition, if the device regularly jams or needs much more frequent modifications, it may be time to seek professional help. Acknowledging these indications early can stop additional damage and guarantee the equipment operates successfully.Complex Fixings Needed

When operators observe persistent indications of breakdown in a strapping equipment, such as unusual noises or frequent jams, it may show the demand for complicated repair work past routine maintenance. In such instances, it is important to evaluate whether the issues originate from internal components like equipments, electric motors, or sensing units, which require specialized knowledge to repair and diagnose. Additionally, issues involving the equipment's electrical systems or software program might require professional intervention. Attempting to address these complexities without appropriate expertise can cause more damage, rising repair work expenses why not try this out and downtime. Because of this, when confronted with elaborate concerns, operators ought to seek the support of trained experts who have the technical abilities and experience essential to bring back the strapping equipment to the finest working problem successfully.Security Worries Included

Safety and security should constantly be a main problem for drivers dealing with strapping machines, specifically when complicated repairs are required. In circumstances including electrical components, high-pressure systems, or elaborate mechanical parts, the danger of injury enhances significantly. Operators should recognize the indications suggesting that professional aid is required, such as strangeness with the maker's devices, relentless malfunctions, or the existence of dangerous materials. It is important to follow safety methods, including putting on suitable individual protective devices (PPE) and making certain the machine is powered down before attempting any kind of repair services. Looking for specialist support not just minimizes threats however additionally assures that fixings are conducted properly, thereby extending the maker's lifespan and maintaining operational efficiency. Focusing on security inevitably protects both employees and tools.Frequently Asked Inquiries

Just how Frequently Should I Solution My Strapping Machine?

Strapping machines must be serviced every six months to assure peak performance. Routine maintenance helps prevent failures, prolongs the equipment's life-span, and warranties consistent strapping top quality, ultimately lowering operational downtime and repair costs.What Are the most effective Brands for Strapping Machine Parts?

Several of the finest brands for strapping machine components consist of Signode, Mosca, and Fromm. These suppliers are understood for their high-grade components, sturdiness, and trustworthy performance, making them popular choices among industry professionals.Can I Fix a Strapping Machine Myself?

Yes, a person can fix a strapping machine themselves if they possess the necessary skills and expertise. Seeking advice from the guidebook and recognizing the maker's components is important to assure safe and effective fixings.How Do I Discover a Professional Technician for Repairs?

To discover a qualified professional for repairs, one ought to look for recommendations from sector peers, get in touch with online evaluations, and verify certifications, guaranteeing the professional possesses appropriate experience with strapping machines for superior service high quality.What Warranty Options Are Available for Strapping Machines?

Numerous warranty choices for strapping machines typically consist of conventional maker service warranties, prolonged service warranties, and service plans. These options differ in duration and protection, making sure protection against flaws and breakdowns for various periods post-purchase.Identifying signs of breakdown in strapping machines is crucial for reliable fixings. When addressing the repair work of a strapping machine, an organized technique is essential to ensure efficient and lasting remedies. Reliable repair work of strapping machines rely heavily on the right tools and devices. When drivers observe relentless signs of breakdown in a strapping device, such as uncommon noises or frequent jams, it might show the need for complex repair work beyond regular upkeep. Security should always be a primary issue for drivers dealing with strapping machines, specifically when complicated repair services are needed.

Report this wiki page